What is an Oilless Bushing?

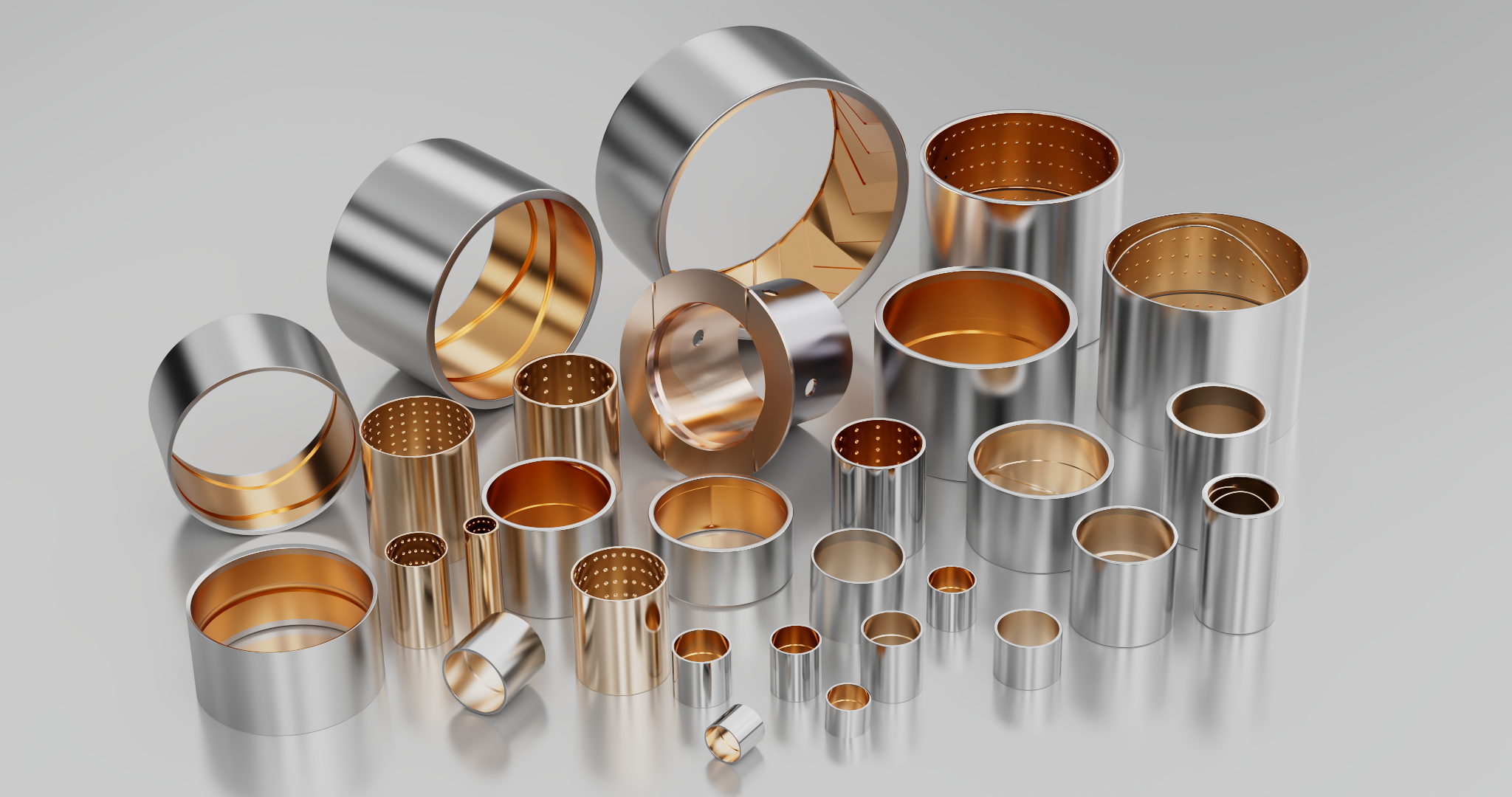

Oilless bushings, also known as sleeve bearings, are a type of self-lubricating sliding bearing. Oilless bushings are used to support sliding motions by reducing friction and increasing stability. Because of their self-lubricating properties and versatility in terms of usage, oilless bushings are a very popular component in industrial applications. Oilless bushings are cylindrical and can be made in any girth and length.

The modern design that is used in today’s oilless bushings has made them extremely popular. The fact that oilless bushings require no maintenance makes them very convenient, and their self-lubricating properties make them long-lasting and highly efficient.

Why is Bronze Used for Bushings?

Bronze is commonly used for oilless bushings because it is a strong and naturally porous metal. Bronze is known to hold up longer than other metals like brass, and its porous composition makes it very effective as a self-lubricating metal. Additionally, bronze is not a very expensive metal and can be easily sourced to create high-quality oilless bushings.

What Materials are Oilless Bushings Made Of?

Oilless bushings are frequently made of bronze powder, which is fused together to create a porous surface in which impregnated oil can be stored. As the bearing is used, the oil continually recycles itself onto the surface of the oilless bushing, making them self-lubricated and justifying the name “oilless bearing.”

When not made of a metal like bronze powder, oilless bushings are made of polymers, plastics, or other synthetic materials. These materials commonly include nylon, PTFE, and others. Plastic oilless bushing is especially noteworthy because they are cheaper, more efficient, longer-lasting, and quieter than their metal counterparts. Choosing plastic oilless bushings means lower costs, less maintenance, and no need to apply grease as they are fully self-lubricating.