Materials

SF-1 Oilless Bushing/SF-2 Marginal Bushing

| Data/Type | SF-1 | SF-2 |

| Base Material |

Steel/Bronze/304/316 Steel ( DIN-St12|ASTM-A366/A366M-97|JIS-SPCC ) + Bronze ( CuSn8Zn3 ) +PTFE +Fillers |

Steel/Bronze/304/316 Steel (DIN-St12|ASTM-A366/A366M-97|JIS-SPCC) +Bronze ( CuSn8Zn3 ) +POM |

| Material Organization |

1.PTFE with lead 0.01~0.03mm 2.Porous bronze 0.2~0.3mm 3.Steel backing 0.7~2.3mm 4.Tin plating 0.005mm or Copper plating 0.008mm |

1.POM with fiber 0.3~0.5mm 2.Porous bronze 0.2~0.3mm 3.Steel backing 0.4~2.2mm 4.Tin plating 0.005mm or Copper plating 0.008mm |

| Max load Capacity P | 140N/mm² | 70N/mm² |

| Friction Coef μ | 0.03~0.18 | 0.05~0.25 |

| Working Temperature | -195°C~+280°C | -40°C~+130°C |

| Speed limit V | 10m/s | 2.5m/s |

| Maximum PV Value |

(Dry)4.3N/mm² m/s (Oil)60N/mm² m/s |

22N/mm² m/s

|

JDB Solid Lubricanting Bushing

| Performance index/Type | CNB-JDB-10 | CNB-JDB-20 | CNB-JDB-30 | CNB-JDB-40 | CNB-JDB-50 |

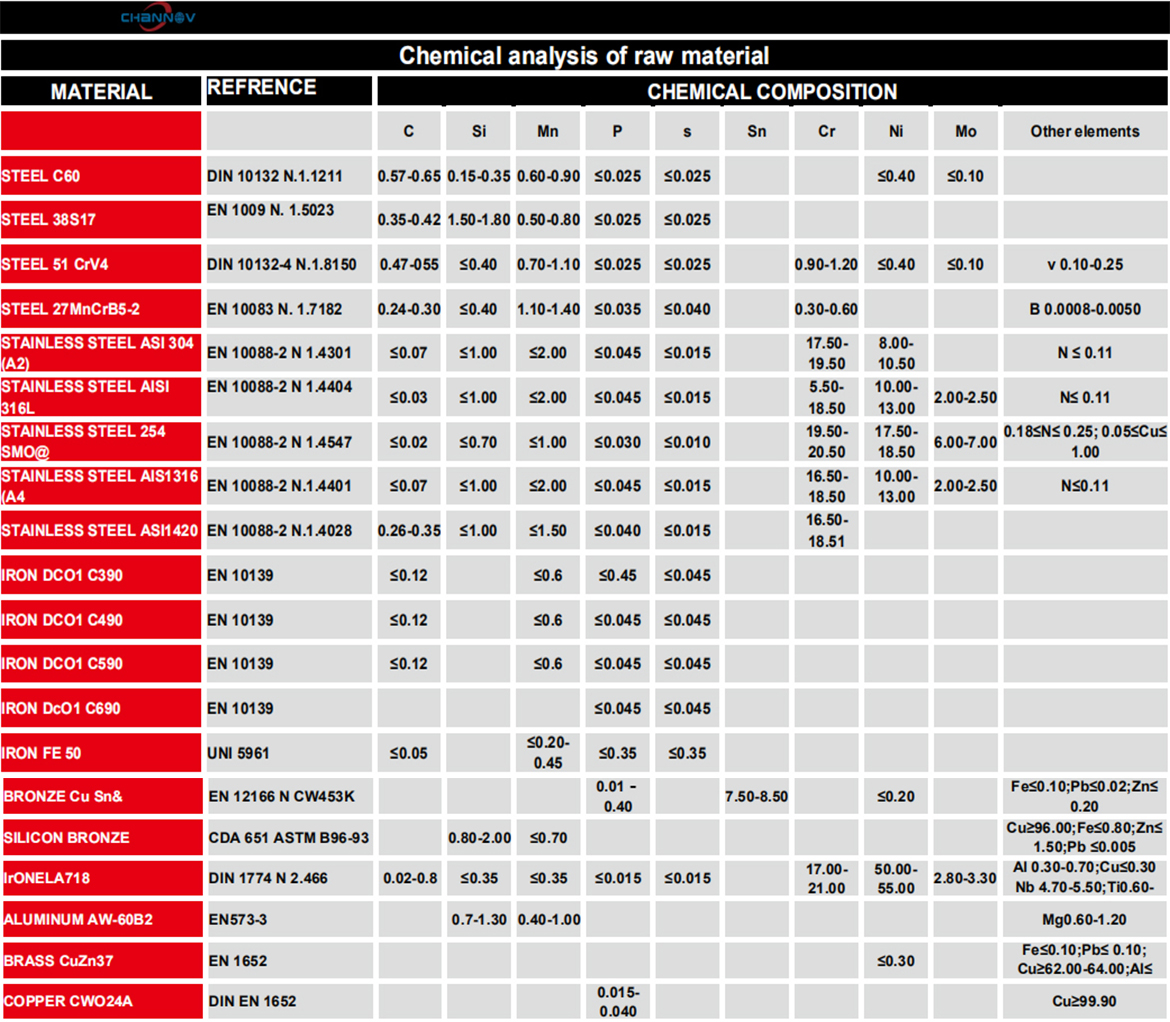

| Material | ZCuZn25Al6Fe3Mn4 | CuSn5Zn5Pb5 | Steel+CuSn6Zn6Pb3 | HT250 | GCR15 |

| Max Move Load Capacity | 100 | 60 | 70 | 250 | 60 |

| Max Sliding Speed | dry0.4 oil0.5 | 2 | 2 | 0.1 | 0.5 |

| Max PV Value Limit | 3.8 | 0.5 | 0.6 | 2.5 | 0.8 |

| Density | 8.0 | 8.0 | 7.6 | 7.8 | 7.3 |

| Tensile Strength | >600 | >250 | >500 | >1500 | >250 |

| Elongation | >10 | >4 | >10 | - | - |

| Hardness | >210 | >80 | >80 | HRC>55 | 160 |

| Max Woking Temperature | 300 | 350 | 300 | 350 | 400 |

| Friction coefficient |

Oil Lubrication:0.03 Dry Friction:0.16 |

- | - | - | - |

FB Bronze Wrapped Bushing

| Type | Material |

| FB090 | CuSn8P0.3 / CuSn6.5P0.1 |

| FB091 | CuSn8P0.3 / CuSn6.5P0.1 |

| FB092 | CuSn8P0.3 / CuSn6.5P0.1 |

| FB094 | CuSn8P0.3 / CuSn6.5P0.1 |

| FB09G | CuSn6.5P0.1 + Gr |

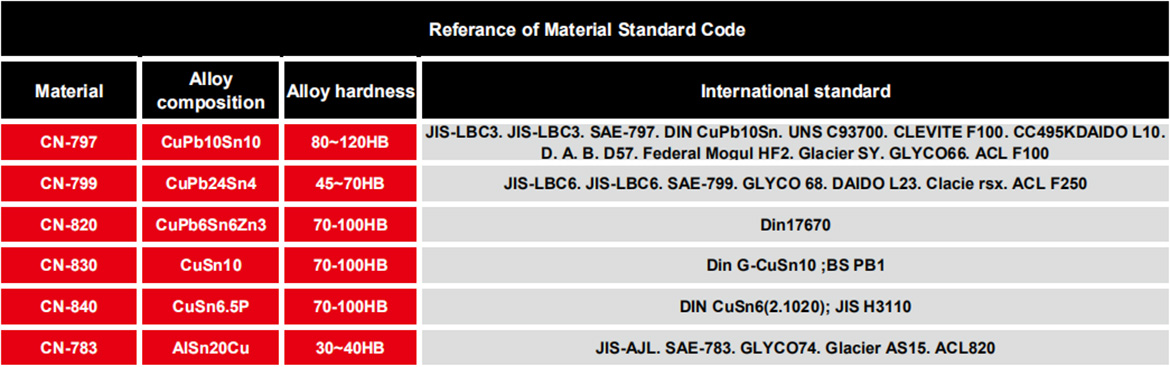

JF Bimetel Bushing

| Material Trademark | Alloy Composition | Alloy Hardness |

| JF-800 | CuPb10Sn10 | 70~100HB |

| JF-720 | CuPb24Sn4 | 45~70HB |

| JF-700 | CuPb30 | 30~45HB |

| JF-20 | AlSn20Cu | 30~40HB |

| JF-930 | CuPb6P0.1 | 69~90HB |

Powder Sintered Bearings

| Data/Type | FU-1 | FU-2 | FU-3 | |

Lock Washers

| Data | Materials | Finish | |||||||

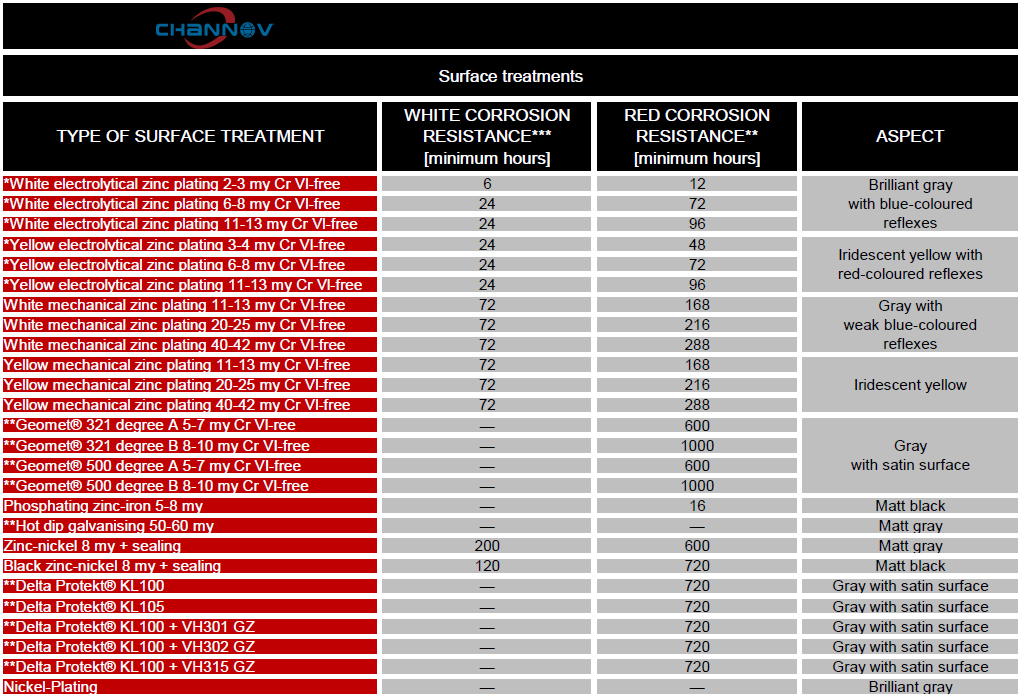

| Wedge lock washers S | 65Mn | S60C | SK5 | 60Si2mN | 51CrV4 | Plated Zinc | Black | Dacromet | Geomet |

| Wedge lock washers SS | SS304 | SS316 | A2 | A4 | Super stainless steel | Poishing | - | - | - |

| DIN6796 | - | - | - | - | - | - | - | - | - |

| DIN6796SS | - | - | - | - | - | - | - | - | - |

| DIN2093 | - | - | - | - | - | - | - | - | - |

| DIN9250 S | 65MN | S60C | SK5 | 60Si2Mn | 51CrV4 | Plated Zinc | Black | Dacromet | Geomet |

| DIN9250 SS | SS304 | SS316 | A2 | A4 | - | Polishing | - | - | - |

| DIN9250 VS | 65MN | S60C | SK5 | 60Si2Mn | 51CrV4 | Plated Zinc | Black | Dacromet | Geomet |

| DIN9250 VSS | SS304 | SS316 | A2 | A4 | - | Polishing | - | - | - |

| DIN471 | 65MN | S60C | SK5 | 60Si2Mn | 51CrV4 | Plated Zinc | Black | Mechanical galvanizing | Phosphating |

| DIN471 SS | SS304 | SS316 | SS420 | A2 | A4 | Polishing | - | - | - |

| DIN472 | 65MN | S60C | SK5 | 60Si2Mn | 51CrV4 | Plated Zinc | Black | Mechanical galvanizing | Phosphating |

| DIN472 SS | SS304 | SS316 | SS420 | A2 | A4 | Polishing | - | - | - |

| DIN6799 | 65MN | S60C | SK5 | 60Si2Mn | 51CrV4 | Plated Zinc | Black | Mechanical galvanizing | Phosphating |

| DIN6799 SS | SS304 | SS316 | SS420 | A2 | A4 | Polishing | - | - | - |

| Satrlock | 65MN | S60C | SK5 | 60Si2Mn | 51CrV4 | Plated Zinc | Black | Mechanical galvanizing | Phosphating |

Spring Spacer bushs

| Data/Type | Elastic cylindrical pin | Positionin bushing |

OEM bearings

| Type | Material | Type | Material |

| AOBO-01 | GCr15 | AOBO-09 | CuZn37Mn3Al2PbSi |

| AOBO-02 | 42CrMo | AOBO-10 | CuSn7-0.2 |

| AOBO-03 | 35CrMo | AOBO-11 | CuAl10Fe3 |

| AOBO-04 | 20CrMo | AOBO-12 | CuAl10Fe5Ni5 |

| AOBO-05 | C45 | AOBO-13 | CuZn25Al6Fe3Mn3 |

| AOBO-06 | 20CrMnTi | AOBO-14 | CuZn25Al6Fe3Mn3 |

| AOBO-07 | CuSn7Zn4Pb7 | AOBO-15 | CuZn35Al2Mn2Fe1 |

| AOBO-08 | CuSn12 | - | - |