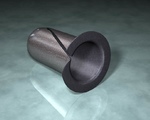

MR-1

Properties

The MR-1 trademark identifies a range of bearings composed of a metal grid housed CuSn6 within PTFE (polytetrafluoroethylene) loaded with solid lubricants (without lead, complying with the European Parliament’s “ELV"directive 2000/53/Ec).

The bronze grid gives the bearings the mechanical strength and the formability required to manufacture the finished parts; the loaded PTFE gives the MR-1 bearings a low friction factor and a high chemical resistance, entirely similar to those features by pure PTFE.

Thanks to their composite structure, the MR-1 bearings provide the best match of mechanical strength, thermal conductivity and low friction factor. The available products are cylindrical and flanged bearings, washers, belts and cast-to-size parts with thickness standard from 0,480 mm, 0,780 and 0,980 (0.019, 0.030 & 0 .039 inch).

Materials

| Support meterail | Stretched Bronze(CuSn6) |

| Intermediate layer | PTFE Modified |

Characteristics

| ·High load capacity |

| Easy mounting |

| Good chemical inertia to corrosive agents |

| High thermal conductivity |

| Negligible water absorption |

| Wide range of service temperatures |

| Minimum overail dimensions and no maintenance |

| Special items available on demand |

Technical Data

| Maximum Specific Load Static | 100 N/mm2 (14500 PSI) |

| Maximum Specific Load Dynamic | 80 N/mm2 (11600 PSI) |

| Maximum Sliding Speed | 1 m/s (200 fpm) |

| Service Temperature Minimum | -200°C (-328°F) |

| Service Temperature Maximum | +260°C (+500°F) |

Pls Scan our customer service whatsapp

Pls Scan our customer service whatsapp