Surface roughness,hardness and plating of the mating axis will have great influence on the capability of the self-lubricating bushing.High-quality surface of the mating axis can prolong the life of the bushing while rough surface will shorten the life of the bushing.

1.Surface roughness of the mating axis

When self-lubricating bushings being used in the condition of fluid lubrication and the surface of the mating axis is faily rough,the convex points on the bushing and its axis will cut the oil film and thus the surface of the axis and the bushing will directly contact with each other.therefore,to improve he capability of the bushing, it requires polishing the surface of the mating axis as smooth as a mirror, thus can reduce the clearance of the oil film and make the film work well.

For most self-lubricating bushings applied in the condition of dry friction or marginal lubrication,a controlled roughness from 0.32 to 1.25 is acceptable and there is no need to polish the surface of the mating axis as smooth as a mirror.

2.Hardness of the mating axis

f there is no hard article in the lubricating condition,good performance can be achieved by using bushing materials and hardness recommended in the following form.If not,it would be better to use the harder material for the mating axis.

| |

Material quality of the axis |

Hardness |

| Self-lubricating bushing |

SS41(Q255B)Common Structural steel

|

Above 220

|

| Self-lubricating bushing |

S25C(25#)Carbon Structural Steel

|

The left column shaft hardness of the material,and so on

|

| Self-lubricating bushing |

SUS.SUH anti-erosion steel(in high temperature and water),and chrome plated steel,etc.

|

The left column shaft hardness of the material,and so on

|

Under running condition with heavy load and rapid swing,the mating axis must be heat-treated.

The after treatment hardness will be decided by the material of the axis.

3.Surface treatment of the mating axis

Aim of this treatment:

a) Improve anti-erosion quality

b)Strengthen surface hardness

c)Smooth the surface and enhance lubricating capability

f the mating axis was plated, it can not only improve the anti-erosion capability but also will enhance the lubricating capability, as with a plated coating,friction can be effectively decreased.Hard oxides and other impurities caused by the axis rust constitute one of the main abrasion causes. Therefore,we recommend the user to have the mating axis chrome plated. If the bushings are going to be used in sea water or similar erosive conditions,their mating axis must be chrome plated for 2 or 3 layers.

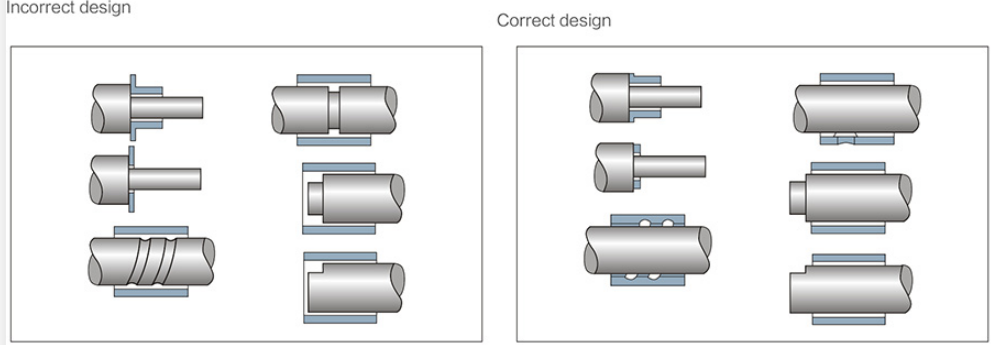

4.Structural design of the mating axis

Surface roughness and keen-edged burrs or dents on the surface of the mating axis will destroy the gliding layer.Please see the following illustration for the qualified mating axis.